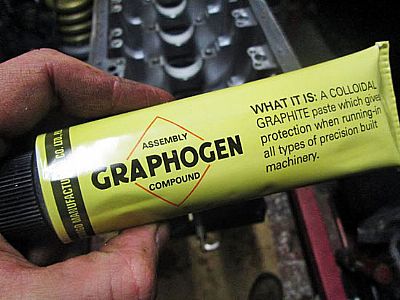

Graphogen 50gram tube

£24.50 £19.99 On Sale!

Where can it be used?

Graphogen can be used on all working surfaces of an engine during assembly, thereby giving the full benefit of the colloidal graphite to the engine parts right from the start. All internal surfaces of moving parts – especially cylinder walls, pistons, bearings, crankshafts, valve stems, camshafts etc can be coated with a liberal layer of Graphogen.

Don't just take our word for it.......

Graphogen has been used for many years, by the likes of Rolls Royce, Lotus, Perkins and Saab, and by many others in the trade. So don't just take our word for it when it comes to how good Graphogen is for engine building. Here are some testimonials.

Lotuselan.net "I started reassembly today (the jack and crankshaft) and coated the surfaces with Graphogen paste after reading Mike Wilkens book.

This is quite an amazing paste which I believe was a product produced prior to the 2nd world war by technicians working on Junkers engines. The paste will disolve once the oil pump starts to take effect so protecting the vital parts at the all important start up phase.

When one applies it there is a good feel factor that the engine is well protected from the outset."

Landrovernet "I've always used Graphogen when building up engines. It will stay in place of as long as you need and provides far superior protection to bearing surfaces when compared to oil based lubricants."

InternationalMR2OwnersClub "On bearing surfaces, I've always used a graphite paste called 'Graphogen'. The reason I used this is because I never knew how long engines would sit around for before being run." "I have used Graphogen for 15 years."

Matt Tomkins, Practical Classics Magazine - used during one of their recent engine rebuilds "It’s a fairly staple product favoured by engine builders and is ideal for classic engine rebuilds, particularly on camshafts to protect them against initial wear of first start-up before the engine gets oil pressure."